Pylontech Battery – Basic Troubleshooting Guide

Quick Check

1. Verify CAN cable connection

Connect the inverter to the ACAN port on the master battery using a standard CAT5e/CAT6 Ethernet cable.

2. Inspect the master battery DIP switch settingsDIP switch configuration required only for master battery, 1st switch is ON, the rest OFF. All slaves battery are OFF.

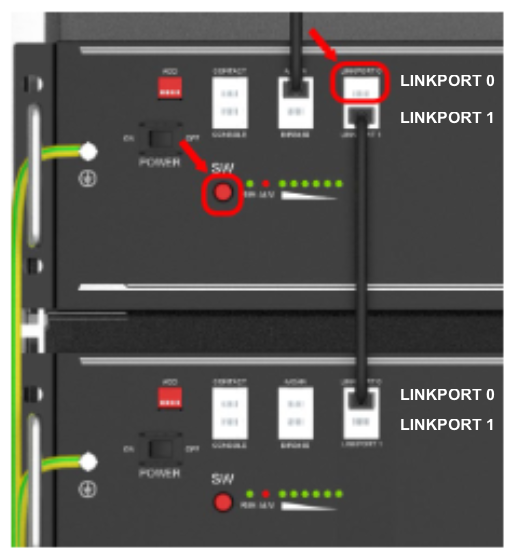

3. Inspect the RS485 links (port 1 to port 0)LinkPort 0: Leave empty (for the Master battery)

LinkPort 1: Connect to LinkPort 0 of the next battery.

Repeat the connection chain for all batteries.

On the last battery, leave LinkPort 1 empty.

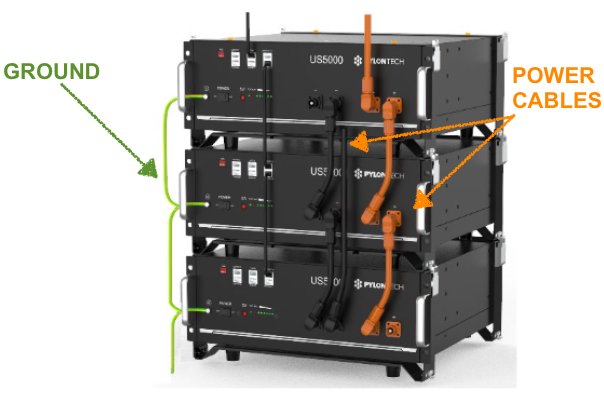

4. Check power cables connectionEnsure that all DC power cables (positive and negative) and ground connections are securely installed in parallel across all battery units, following the wiring reference provided in the diagram below.

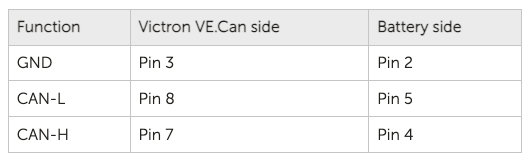

5. CAN cable checkIf all cable communication checks have been completed but the inverter still does not detect all batteries, inspect the dedicated CAN cable (RJ45). Verify that the default wiring and pinouts are intact. Some installers may have modified the cable during installation.

DEYE: only pins 4 and 5 are used for inverter-to-battery communication.

VICTRON:

Connect the inverter to the ACAN port on the master battery using a standard CAT5e/CAT6 Ethernet cable.

DIP switch configuration required only for master battery, 1st switch is ON, the rest OFF. All slaves battery are OFF.

LinkPort 0: Leave empty (for the Master battery)

LinkPort 1: Connect to LinkPort 0 of the next battery.

Repeat the connection chain for all batteries.

On the last battery, leave LinkPort 1 empty.

Ensure that all DC power cables (positive and negative) and ground connections are securely installed in parallel across all battery units, following the wiring reference provided in the diagram below.

If all cable communication checks have been completed but the inverter still does not detect all batteries, inspect the dedicated CAN cable (RJ45). Verify that the default wiring and pinouts are intact. Some installers may have modified the cable during installation.

DEYE: only pins 4 and 5 are used for inverter-to-battery communication.

VICTRON:

Turn ON the power switch on each battery unit.

No lights will appear yet — this is expected.

Press and hold the red SW (Power) button for 1–2 seconds on the MASTER ONLY

LED indicators will light up on each battery sequentially .

The batteries will auto-address sequentially.

For US5000B models:

Turn ON the breaker switch on each battery.

This allows current flow after the stack is energized.

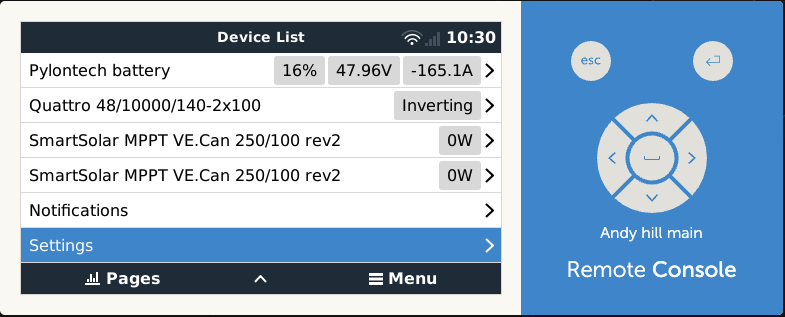

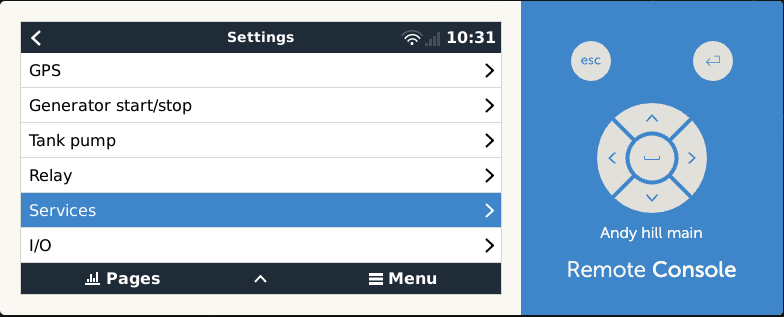

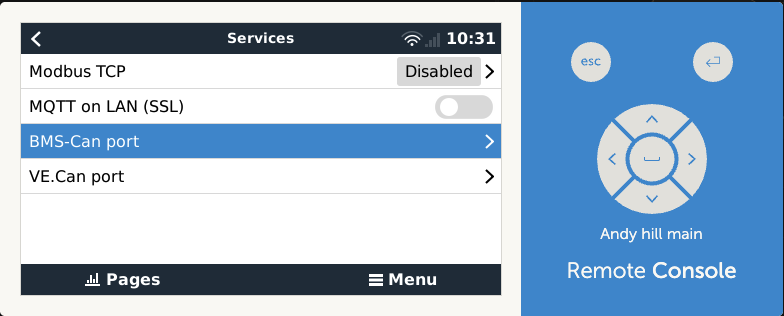

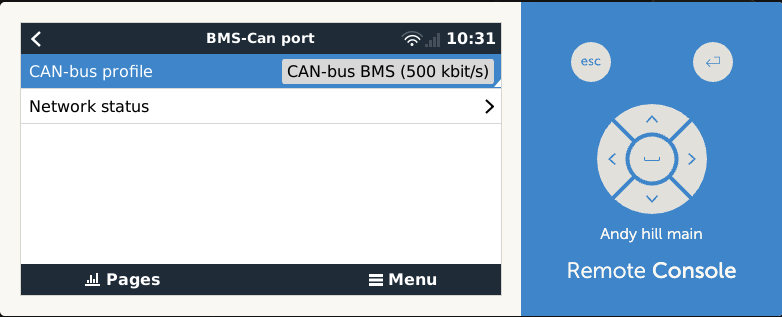

🔧 CAN-Bus Configuration for Victron only

After the hardware setup:

Go to Settings > Services > BMS-CAN port on the Victron GX device (e.g., Cerbo GX).

Set the CAN-bus profile to:

➤ 500 kbit/s

This ensures stable communication between the Victron system and Pylontech batteries.

After the hardware setup:

Go to Settings > Services > BMS-CAN port on the Victron GX device (e.g., Cerbo GX).

Set the CAN-bus profile to:

➤ 500 kbit/s

This ensures stable communication between the Victron system and Pylontech batteries.

⏹️ Shutdown Procedure

To safely shut down the Pylontech battery system:

Turn OFF the DC breaker (lower left side).

Switch OFF the breaker (if using US5000B) on each battery.

Press and hold the red SW (Power) button on each battery for 1–2 seconds until all LEDs turn off.

Turn OFF the battery’s power switch (on the side or rear, depending on the model).

⚠️ Always perform shutdown in this order to avoid communication or protection faults.

To safely shut down the Pylontech battery system:

Turn OFF the DC breaker (lower left side).

Switch OFF the breaker (if using US5000B) on each battery.

Press and hold the red SW (Power) button on each battery for 1–2 seconds until all LEDs turn off.

Turn OFF the battery’s power switch (on the side or rear, depending on the model).

⚠️ Always perform shutdown in this order to avoid communication or protection faults.

🔋

How to Check if Battery is Working

For Victron ➡ Click here.

For Deye ➡ Click here.

Related Articles

Pylontech Battery - Basic Troubleshooting Guide (Batteries not discharging - Battery Monitor [512] Internal Failure Alarm)

Once this is reported by the customer, we must first request for photos of the whole setup to check any wiring/connection anomalies. Then confirm the number of affected batteries by following the steps below 1: On the VRM portal, Go to Remote Console ...Understanding Battery Cell Imbalance

Battery banks configured in parallel are common in solar energy storage systems. While parallel configurations increase amp-hour (Ah) capacity and enable higher energy reserves at a constant voltage, they also introduce a critical challenge: State of ...BSL Battery – Basic Troubleshooting Guide

Use this guide when setting up a BSL battery stack, or if your BSL batteries are connected but not working. Quick Check Verify CAN cable connection The cable from the inverter must be connected to the CAN port of the master battery. Inspect the RS485 ...How to Fix Battery Cell Imbalance (BSL Battery)

A battery cell imbalance may present through unusual SOC (State of Charge) behavior, red LED indicators, or system instability. If one battery in the stack is out of balance, it can cause inconsistent charging and affect overall performance. The goal ...Sungrow Troubleshooting

Use this guide a checklist when troubleshooting a faulty Sungrow system. 1. I have reset my system Turn the system off You Sungrow inverter will have the solar panels connected and a AC switch that connects to the switchboard. 1. Turn off the PV ...